The company was founded in the early 1980s and is a mechanical manufacturing enterprise that integrates the research, development, production and sales of .

Over the years, the company adheres to the "quality, integrity" concept of production and management. Based on the innovation and innovation of powder machinery.

With excellent production team and excellent production equipment, to provide customers with superior products and premium services.

Haicheng Jin Lun Mining Machinery Co., Ltd.

Contact: Manager Lang

Telephone: 13604124805

Fax: 0412-3214668

Address: Haicheng red light industrial park

Web site: www.jlksjx.com

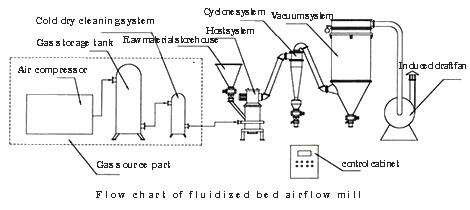

Working principle

Compressed air is accelerated by Lawal nozzle to supersonic airflow and then injected into the grinding area to make the material fluidization. In the crushing area, the accelerated materials converge at the intersection points of the nozzles. Here, the particles collide with each other. The crushed material is transported to the classification zone by negative pressure updraft, and the fine powder which reaches the grain size is selected by the internal grading wheel. The coarse powder which is not satisfied with the grain size is returned to the comminuted area to continue to comminuted (no large particles are produced). The qualified fine powder is collected with the air flow into the cyclone separator, and the dusty gas is filtered and purified by the bag filter and then discharged into the atmosphere.

Product features

The horizontal grading wheel is adopted for classification, and the cutting accuracy is more accurate and the grading efficiency is higher than the vertical grading wheel.

The aerodynamics principle proves that the larger the grading wheel, the more bad points of classification. Therefore, the equipment adopts high-speed and small grading wheels to ensure the classification accuracy, which is more than 1 times higher than that of the domestic large wheel and low speed airflow grinding.

After special flow field design and high precision machining, the energy consumption of airflow mill is reduced by 30% compared with disc type and cyclone type.

The high speed particles do not collide with the wall of the crushing chamber. The material is not passed through the nozzle, and the wear is low, and the product is free from contamination.

The yield is serialized: 2~5000 kg/h; fineness is high: d97=2 to 180 m.

The particle shape is good, the particle size distribution is narrow, and there is no big particle.

Program control, imported components, man-machine interface is good, easy to operate.

The stepless adjustable, stable operation, thorough cleaning, easy to replace varieties.

A wide range of applications, compact structure, low noise, suitable for Mori hardness less than 9.5 of all kinds of soft and hard material grinding.

Widely used in chemical, non-metallic minerals, metallurgy, abrasives, ceramics, refractories, medicine, pesticides, food, health products, new materials and other industries.