The company was founded in the early 1980s and is a mechanical manufacturing enterprise that integrates the research, development, production and sales of .

Over the years, the company adheres to the "quality, integrity" concept of production and management. Based on the innovation and innovation of powder machinery.

With excellent production team and excellent production equipment, to provide customers with superior products and premium services.

Haicheng Jin Lun Mining Machinery Co., Ltd.

Contact: Manager Lang

Telephone: 13604124805

Fax: 0412-3214668

Address: Haicheng red light industrial park

Web site: www.jlksjx.com

Jaw crusher

Jaw crusher is mainly used for crushing various ores or bulk materials in medium size. According to the width of the inlet, it is divided into three kinds of large, medium and small size. The width of the inlet is larger than 600mm, the width of the inlet is 300-600mm, and the width of the inlet is less than 300mm. Jaw crusher (jaw break) is widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries. The highest compressive strength of the broken material is 320Mpa.

Working principle

The working part of the jaw crusher consists of two jaw plates, one is the fixed jaw plate (fixed jaw), the vertical (or the upper end is slightly extroverted) fixed on the front wall of the body, the other is the movable jaw (moving jaw), the position is tilted, and the small and small crushing cavity (working cavity) is formed with the fixed jaw plate. The movable jaw plates do periodic reciprocating movements against the fixed jaw plates, sometimes apart, sometimes approaching. When the material is separated, the material goes into the crushing chamber and the finished product is unloaded from the lower part; in close proximity, the material between the two pieces of the jaw is crushed, bending and splitting.

The main components of the jaw crusher:

1. stand

The frame is a four wall rigid frame with an upper and lower opening, which is used as a support to support the eccentric shaft and to withstand the reacting force of the broken material. It requires sufficient strength and stiffness. The cast steel is generally cast as a whole, and the minicomputer can also be replaced by high quality cast iron. The rack of the mainframe needs to be segmented and bolted to form a whole and the casting process is complicated. The frame of the self-made small jaw crusher can also be welded by thick steel plate, but the rigidity is poor.

2. jaw plate and side panel

The fixed jaw and the movable jaw are made up of the jaw bed and the jaw plate. The jaw plate is not separated from the work, and is fixed on the jaw bed with bolts and wedge iron. The jaw of the fixed jaw is the front wall of the frame, and the movable jaw and jaw are suspended at the top of the week, with sufficient strength and stiffness to withstand the broken forces, and most of them are cast steel or cast iron.

3. transmission parts

The eccentric shaft is the main shaft of the crusher, which is made of high carbon steel by a large bending torsion force. The eccentric part must be fined, heat-treated, and bearing bushing cast with Babbitt alloy. One end of the eccentric shaft is loaded with a wheel, and the other end is equipped with a flywheel.

4. regulator

The adjusting device includes wedge type, cushion type and hydraulic type. Generally, wedge type is used, which consists of two pieces of wedges. The front wedge can move back and forth to hold back plate. The rear wedge is a adjusting wedge. The wedge can move up and down, the slope of the two wedge is inverted, and the screw makes the rear wedge move up and down and adjust the size of the material mouth. The outlet regulation of the small jaw crusher is realized by increasing the number of gaskets between the thrust plate support and the frame.

5. flywheel

The flywheel of jaw crusher is used to store the energy of moving jaw when it is empty, then it is used for industrial formation, so that the mechanical work meets the trend of uniformity. The wheel also plays the role of the flywheel. Flywheels are often made of cast iron or cast steel, and the flywheels of minicomputers are often made into integral ones. When the flywheel is made, the static balance should be paid attention to when it is installed.

6. lubricating device

Eccentric shaft bearings usually use centralized circulation lubrication. The supporting surface of mandrel and thrust plate is usually lubricated by manual grease gun. The swing angle of the movable jaw is very small, so that the lubrication between the axis and the axle bush is difficult. It often opens a number of axial oil trenches at the bottom of the axle bush. It is connected to the oil trough in the middle, and then the oil pump is forced into the dry butter to lubricate it.

This series of products has the characteristics of large crushing ratio, uniform product size, simple structure, reliable operation, simple maintenance, and economical operation cost. It is widely used in many industries, such as mine, smelting, building materials, highway, railway, water conservancy and chemical industry, and crushing all kinds of materials with compressive strength less than 320 MPa.

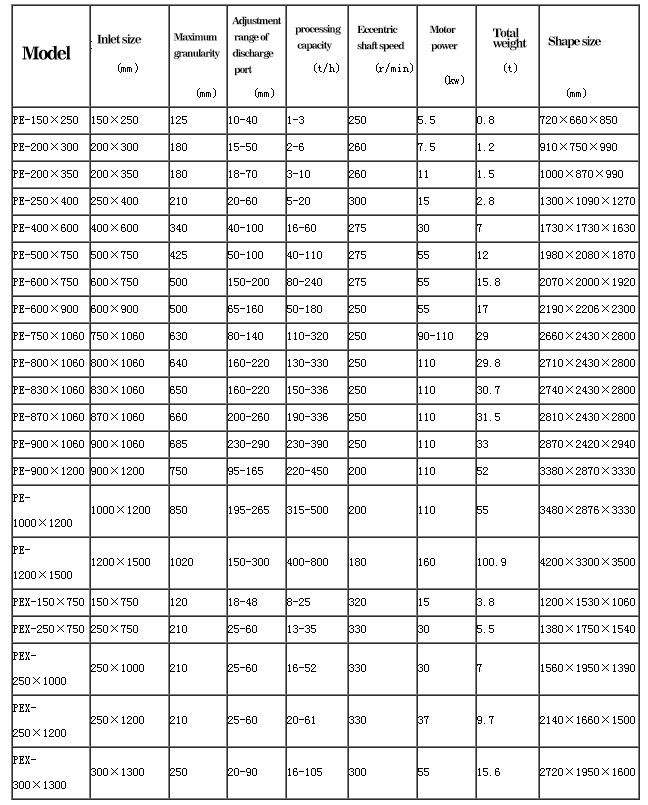

PE, PEX series jaw crusher is a complex swing type crushing equipment, suitable for metallurgy, mining, construction, transportation, cement and other departments, as coarse crushing, crushing strength under the 300Mpa of various ore or rock. It has the advantages of simple and reasonable structure, high yield, large crushing ratio, long life of tooth plate, uniform grain size, low power consumption, convenient maintenance and so on. It is the most advanced model in China at present.

The breaking mode of the series crusher is a curved extrusion type. Its working principle is that the motor drives the belt and the pulley to move the moving jaw through the eccentric axis, and when the moving jaw rises, the angle between the elbow plate and the movable jaw becomes larger, thus pushing the movable jaw to close to the fixed jaw plate, while the material is crushed or chopped to break. Objective: when the moving jaw is down, the angle between the elbow plate and the movable jaw is smaller, and the movable jaw leaves the fixed jaw plate under the action of the pull rod and spring, and the broken material is discharged from the lower mouth of the crushing cavity. With the continuous rotation of the motor, the mobile jaw is broken and discharged, and the batch production is realized.

Jaw crusher is mainly used as coarse crusher and medium crusher in mining, building materials, infrastructure and other departments. According to the width of the inlet, it is divided into three kinds of large, medium and small size. The width of the inlet is larger than 600MM, the width of the inlet is 300-600MM, and the width of the inlet is less than 300MM.

The working part of the jaw crusher is two pieces of jaw plate, one is fixed jaw plate (fixed jaw), the vertical (or the upper end slightly extroversion) is fixed on the front wall of the body, the other is the movable jaw plate (moving jaw), the position is tilted, and the small broken cavity (working cavity) is formed with the fixed jaw plate. The movable jaw plates do periodic reciprocating movements against the fixed jaw plates, sometimes apart, sometimes approaching. When the material is separated, the material goes into the crushing chamber and the finished product is unloaded from the lower part; in close proximity, the material between the two pieces of the jaw is crushed, bending and splitting.

Description of the use of jaw crusher

(1) the preparatory work of the jaw crusher before starting

1, we should carefully check whether the lubrication condition of the bearing is good, and whether there is enough grease in the elbow plate joint of the bearing.

2, check carefully whether all fasteners are fully fastened.

3, whether the protective device is good and find the unsafe phenomenon should be eliminated immediately.

4, check whether there is any ore or other debris in the crushing cavity, if any, remove it immediately.

(two) starting of jaw crusher

1. After checking and proving that the machine and transmission part is normal, it can start.

2, this machine can only start without load.

3. If you find abnormal conditions after starting, you should stop immediately. If you want to find out the cause and remove the hidden danger, you can start again.

(three) maintenance and use of jaw crusher

1. After the crusher is running normally, the material can be cast.

2, to be broken materials should be evenly added to the crushing cavity, and should avoid side feeding, to prevent sudden changes in load or unilateral sudden increase.

3. Under normal working conditions, the temperature rise of the bearing should not exceed 35 degrees C, the maximum temperature should not exceed 70 degrees C, otherwise it should stop immediately and find out the reason to eliminate it.

4, before stopping, should first stop feeding, until the crushing chamber is completely emptied after crushing material, just turn off the motor.

5. During use, if the machine is stopped due to material blockage in the crushing cavity, the motor must be shut down immediately, and the material must be removed before it can be used again.

6, one end of the jaw is worn after wearing.

(four) lubrication of the jaw crusher

1, pay attention to the lubrication work of the friction surface in time to ensure the normal operation and prolong the service life of the machine.

2. The grease used for this machine should be determined according to the location and temperature. Generally, calcium base, sodium base or calcium sodium grease can be used.

3, the grease of the bearing seat is 50 - 70% of its volume, and must be replaced every three months; clean oil or kerosene must be used to clean the bearing and the dirt in the bearing seat for new oil.

4, elbow plate and elbow pad contact before the machine starts, must be added grease.